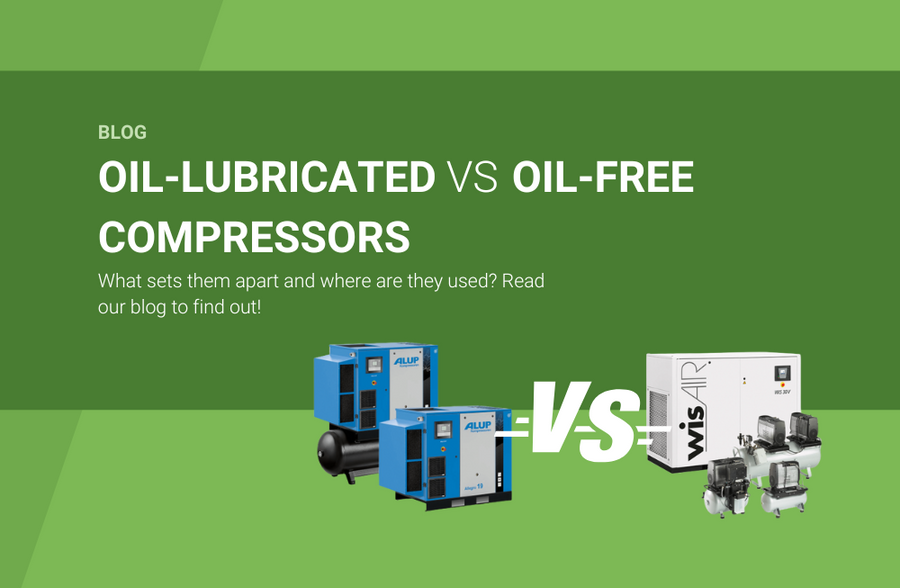

Compressors form the backbone of compressed air systems, which are used to power machines, clean parts, or operate measuring instruments. Compressors are not all the same. They can be classified into oil-lubricated and oil-free compressors. In this blog, we will explain exactly what these types entail, highlight the key differences, and discuss what you should consider when choosing between them.

What does a compressor do?

Starting with the basics, a compressor is a machine that compresses air to a higher pressure. This compressed air is then used as an energy source for a wide range of applications. It can power tools in a workshop or supply clean air in environments such as laboratories.

Compressors are widely used in industries, healthcare facilities, laboratories, and food production. Since requirements differ per sector, the type of compressor used also varies.

What is the difference between oil-lubricated and oil-free compressors?

The difference between these two types lies in how the moving parts are lubricated/cooled and the impact this has on air quality.

Oil-lubricated compressors

Oil-lubricated compressors use oil to lubricate the mechanical parts. This prevents wear and ensures efficient operation. However, during the compression process, a small amount of oil can enter the compressed air. To remove this oil, additional filters are often used, with activated carbon being indispensable.

Oil-lubricated compressors are powerful, durable, operate quietly, and are suitable for intensive use. However, they do not deliver completely oil-free air and require regular oil changes.

Oil-free compressors

Oil-free compressors do not use oil during the compression process. Instead, they employ other techniques such as coatings or dry bearings. The compressed air produced is therefore oil-free, which is essential for applications where air purity is of the highest importance.

Oil-free compressors generally require less filtration and maintenance and provide a high degree of air purity. On the downside, they typically come with higher purchase costs, a shorter lifespan due to faster wear, and a higher noise level compared to oil-lubricated models. Additionally, oil-free compressors have limited capacity. It is also important to remove oil vapor from the intake air, as the quality of the intake air largely determines the quality of the compressed air.

Why is there a difference?

The difference in design arises from the need for different air qualities. In some applications, no contamination whatsoever, however small, can come into contact with the process or product. Think of the pharmaceutical industry, hospitals, or food production. Here, oil-free air is an absolute requirement.

In less critical environments, such as workshops or general production halls, an oil-lubricated compressor is often sufficient, especially if good post-treatment is used to clean the air.

Applications of oil-lubricated compressors

- Industrial machines and tools: For applications where power is more important than air purity, such as operating pneumatic tools or air-powered machinery.

-

Garage and workshop environments: Oil-lubricated compressors are robust and reliable and often used for paint spraying, tire inflation, or pneumatic tools.

-

Production without strict hygiene rules: When minimal oil residues are acceptable, oil-lubricated solutions are usually more cost-effective or even desirable, for example, for lubricating air tools.

Applications of oil-free compressors

- Pharmaceutical and medical sector: Hospitals, pharmacies, and drug manufacturers cannot risk contamination. Oil-free air is a requirement here.

-

Food industry: In food packaging or processing, air purity is crucial. Oil traces can affect taste, smell, or food safety. Oil-lubricated machines using food-grade oil can also be a suitable alternative.

-

Laboratories and cleanrooms: In sensitive research environments, air must be pure to guarantee reliable measurements and results.

-

Electronics industry: Clean air is needed for dust-free production and assembly of sensitive components.

What is the right choice for your situation?

The choice between an oil-lubricated or oil-free compressor depends greatly on your application, the required air quality, and your budget. Oil-free compressors are ideal if the compressed air comes into direct contact with sensitive processes or products. Oil-lubricated models are more powerful, cost-effective, and suitable when extremely high air purity is not required or when a post-treatment system is used. For high capacity or continuous use, an oil-lubricated compressor combined with filtration and adsorption through activated carbon and/or food-grade oil is an ideal solution. This can even make it possible to produce completely oil-free air in the end.

Compressors at Avilo

At Avilo, we offer both oil-lubricated and oil-free compressors tailored to your application.

Would you like to know which compressor suits your situation best? Please feel free to contact us. Our specialists are happy to provide you with free advice.

EN

EN

NL

NL